Let's Sail with Confidence!

Ahoy, maritime mates! Safety, compliance, and flawless operations form the anchors of success in our industry. That’s why Eurroseas is here to offer comprehensive Surveys and Inspection services by ensuring your vessels remain shipshape.

Our crew of surveyors and inspectors possesses extensive knowledge of international maritime regulations and industry best practices. They dive deep into inspections, leaving no stone unturned to ensure your vessel meets all requirements. With their keen eyes, they provide valuable insights and recommendations by guiding you on the right course. Be it surveys conducted by Port States, Flag States, or trusted organizations, we’ve got you covered, aligning with ILO, ISM, STCW, and other relevant bodies.

We have a proven track record of successful surveys and inspections for various vessels across Europe and UK ports, earning the trust of shipowners and operators. Understanding the importance of time in the maritime world, our efficient team sails smoothly and minimizes disruptions to your vessel’s operations. You can rely on us for prompt and detailed inspection reports.

Annual Survey

During the annual survey, we conduct various essential tasks to ensure the vessel’s safety and compliance. These include testing and inspecting cargo piping and ballast tanks, as well as verifying the adequacy of corrosion protection in crude oil tanks. Additionally, we thoroughly examine all areas of the vessel to identify any potential oil or water leakages. As part of the survey, we also test the functionality of remote controls for components such as fans and oil fuel pumps. Our meticulous approach guarantees that all critical aspects are carefully assessed and maintained for the vessel’s optimal performance and safety.

Renewal Survey

The Renewal Survey conducted every five years, is a mandatory requirement to renew the vessel’s certificate of documentation. This comprehensive survey encompasses various aspects, including a thorough inspection of the hull and machinery. Additionally, the survey involves a detailed examination of the vessel’s cargo gear and other equipment. By undertaking these essential inspections, we ensure the vessel meets the necessary standards and regulatory compliance for the renewal of its documentation certificate.

Class Survey

The Class Survey, conducted annually for class confirmation, serves the purpose of verifying the ship’s compliance with the class conditions to a satisfactory extent. It also includes the inspection of machinery, devices, and installations that fall under the requirements outlined in the Rules for the Classification and Construction of Sea-Going Ships. This survey ensures that the ship meets the necessary standards and regulations set forth by the classification society, guaranteeing its continued adherence to the prescribed guidelines for the safe operation and construction of sea-going vessels.

Dry Dock Survey

During the dry dock survey, the vessel is taken out of the water to allow the surveyor to thoroughly examine all elements of the ship, including those typically submerged below the waterline. The presence of saltwater can cause certain metals to undergo reactions that may result in problems such as corrosion and deterioration. Thus, the dry dock survey presents an ideal opportunity to assess the stability of the hull. Surveyors employ advanced techniques like ultrasonic thickness testing, which involves sending ultrasound waves through the ship’s metal components. This method provides a detailed analysis of the hull’s structural integrity, offering valuable insights into its overall condition.

Safety Construction

The safety construction survey meticulously examines all the structural components of a vessel. The surveyor conducts a survey and inspection to identify any signs of excessive corrosion on the deck and hull, ensuring that the vessel’s integrity remains intact. In addition to this, the safety construction survey also assesses other critical elements, which include:

- Watertight doors

- Draining systems

- Bilge pumping

- Fire protection and fixed fire-fighting equipment

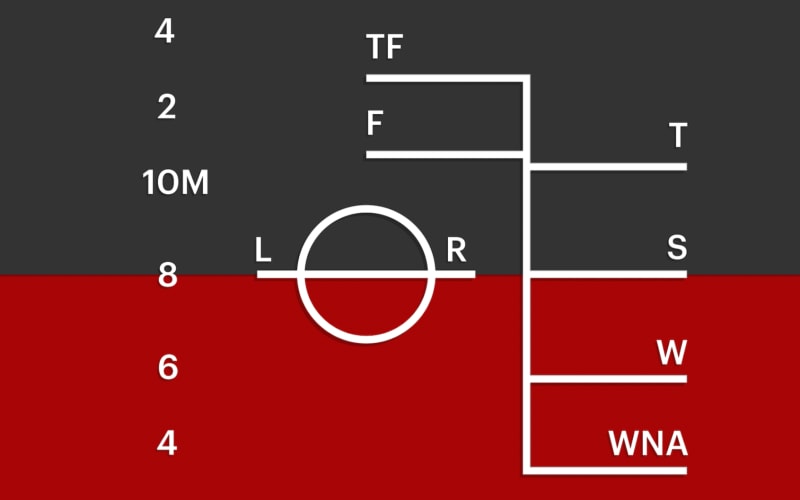

Load Line

The load line survey is conducted to verify the condition of multiple ship components, ensuring the hull remains watertight below the freeboard level and weathertight in all areas above it. During this survey, the surveyors thoroughly examine various aspects, including the hull for any cracks, the integrity of locking bars, side scuttles, and the functionality of watertight hatch openings. The objective is to confirm that the ship meets the requirements for maintaining its watertight and weathertight characteristics, promoting the safety and security of the vessel and its crew.

Cargo Ship Safety Equipment

The cargo ship safety equipment survey will analyze the management, compliance, and effectiveness of the safety systems on the vessel. The surveyor will ensure safety manuals such as the muster list and stations, lifejacket instructions, survival craft launching instructions, and fire control plans are visible and accessible. Other safety systems the surveyor will check include:

- Fixed fire-fighting equipment

- International shore connections

- Fire detection systems

- Emergency lights and alarms

Terminal Safety

The terminal safety survey is crucial to ensure the readiness of ships in responding to emergencies throughout cargo transfer operations, including pre, during, and post-operations. This survey evaluates the functionality of safety and navigation systems and thoroughly examines the propulsion and steering gear. Failing to meet the requirements of a terminal safety survey can lead to the vessel being blacklisted, emphasizing the significance of a comprehensive and effective emergency response plan for ships.

Pre-Purchase Survey

The pre-purchase survey encompasses a wide range of areas to ensure a thorough assessment before finalizing a purchase. Our services encompass the examination of the hull and structural integrity, machinery and equipment, safety systems, environmental compliance, and various other crucial aspects. This comprehensive survey aims to provide a comprehensive understanding of the condition and suitability of the vessel, assisting potential buyers in making informed decisions.

Annual ISM Audits

The External Safety Audit, commonly referred to as the Annual ISM Audit conducted by the flag state, follows a comparable procedure and framework to the internal audit. This audit is performed by an external entity authorized by the flag state to ensure compliance with the International Safety Management (ISM) Code. Similar to the internal audit, the External Safety Audit assesses various aspects of the ship’s operations, safety management system, and compliance with international regulations.

Vetting inspections

Vetting inspections, widely recognized as OCIMF SIRE inspections (Ship Inspection Report Programmer), are renowned in the tanker industry. These inspections are aimed at enhancing the accessibility of ship inspection information and promoting ship safety. On average, over 600 SIRE inspections are conducted monthly. The Oil Companies International Marine Forum (OCIMF) has developed the Vessel Inspection Questionnaire (VIQ) for oil tankers and a CDI checklist for Chemical tankers. These questionnaires and checklists encompass various aspects of shipboard operations, management systems, and compliance with established requirements. The inspection results are subsequently uploaded to the SIRE website, providing valuable insights and transparency to the industry.

Port State Inspections

Administrations conduct Port State Inspections to ensure compliance with mandatory rules and regulations for foreign flag ships visiting their ports. In cases where clear grounds for significant deficiencies related to operational requirements of international conventions (such as SOLAS and MARPOL) are identified, a Port State has the authority to detain a ship, preventing it from proceeding to sea. This inspection serves as a vital measure to uphold safety and regulatory standards within port jurisdictions.